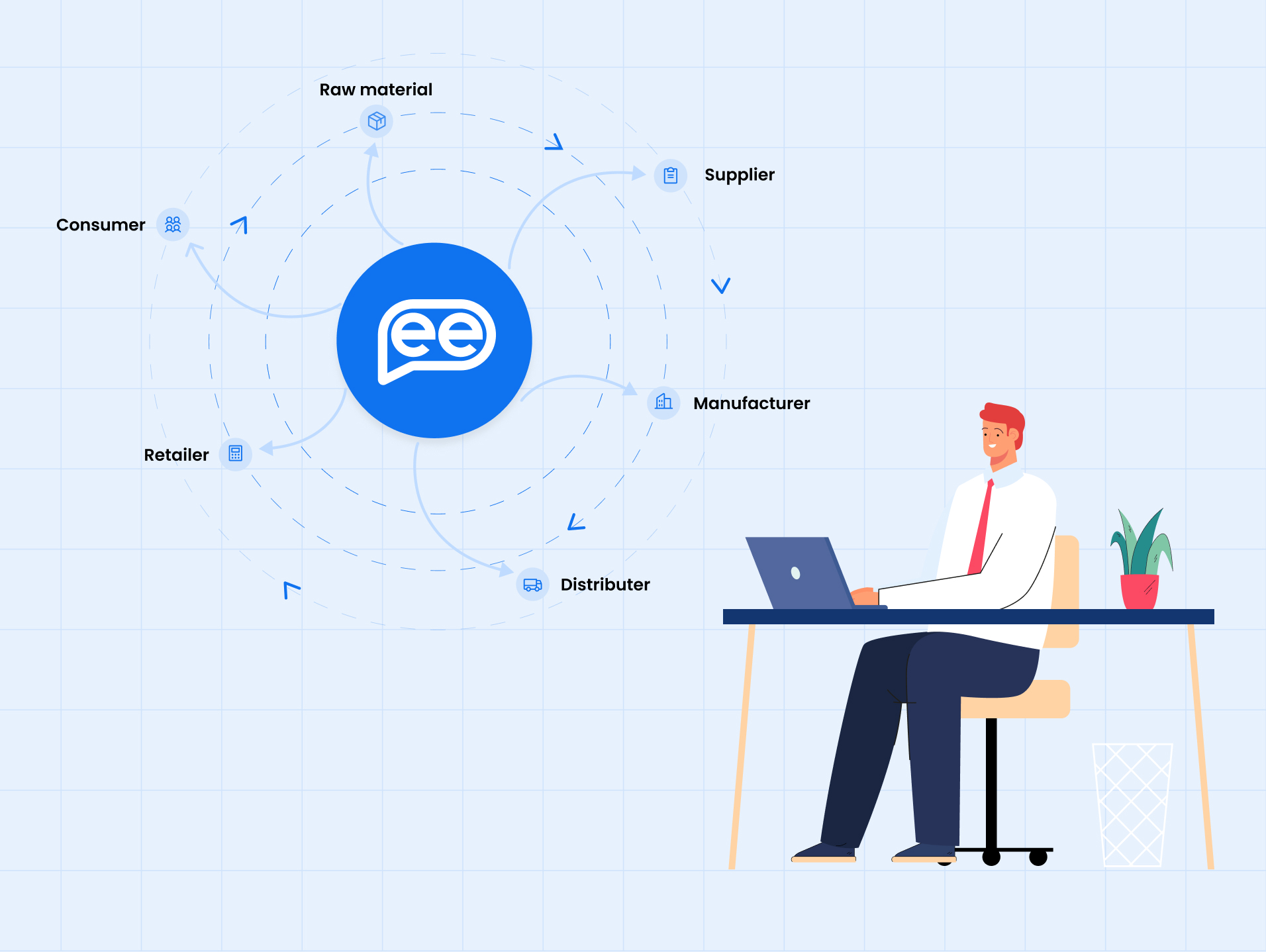

In today’s business world, which is always changing, supply chain speed and automation have become crucial for companies that want to do well in a competitive market. A well-run supply chain management system is the heart of any successful business. It allows goods and services to flow smoothly from suppliers to customers and, in the end, shapes the customer experience as a whole. Companies are seeking the help of artificial intelligence (AI) to change their supply chain processes because they know they need to use cutting-edge technologies to get a strategic edge.

There is a lot of AI hype, and it’s nothing new for many in procurement and supply chain. Yet, these models are only getting better, and the speed of improvement has never been faster. Generative AI has gotten a lot of attention because it has the ability to completely transform the way a supply chain is managed. Generative AI is different from traditional AI because it uses machine learning algorithms to create new content, data, or solutions based on patterns learned from existing data. This gives it a unique set of abilities that set it apart from traditional AI.

“Integration of AI and supply chain management make the decision-making process easier and faster, improve efficiency, and better human resource utilization. AI has helped enterprises, businesses, brands, and retailers make better decisions across their supply chains.” – indianretailer.com

In this blog, we set out to find out how generative AI is changing the way supply chain management is done. We will talk in-depth about how generative AI is better than standard AI when it comes to dealing with the changing challenges and complexity of the modern supply chain. As we learn more about the use cases and uses of generative AI in different supply chain scenarios, we will see how it can improve supply chain optimization and make automation more seamless.

Join us as we explore the unrealized promise of generative AI and find out how it can be used to find new solutions, improve processes, and respond quickly to changes in the market. By the end of this ebook, you will have a deep understanding of how generative AI is changing supply chain management paradigms and how it is at the forefront of innovation, giving organizations the power to create a new era of supply chain practices that are efficient, responsive, and customer-centered.

How Generative AI Enhances Supply Chain Optimization

According to IBM’s recent report, AI is becoming essential to innovative supply chain transformation. Forty-six percent of supply chain executives anticipate that AI/cognitive computing and cloud applications will be their greatest areas of investment in digital operations over the next three years.

Generative AI, a subset of artificial intelligence, leverages machine learning algorithms to generate new content, data, or solutions based on patterns learned from existing data. In the realm of supply chain management, generative AI’s ability to understand complex relationships and patterns makes it a powerful tool for optimization. Here’s how generative AI can enhance supply chain optimization:

Demand Forecasting

Demand Forecasting

Generative AI analyzes historical sales data, market trends, and other relevant factors to accurately predict future demand for products. By leveraging this forecasting capability, companies can optimize their inventory levels, minimize stockouts, and reduce excess inventory, resulting in cost savings and improved customer satisfaction.

Predictive Maintenance

Predictive Maintenance

Generative AI examines sensor data from equipment and machinery to predict maintenance needs before failures occur. This proactive approach helps reduce downtime, ensures smoother supply chain operations, and extends the lifespan of assets, ultimately leading to increased operational efficiency and reduced maintenance costs.

Inventory Management

Inventory Management

Generative AI optimizes inventory levels by considering lead times, demand fluctuations, and supplier capabilities. Maintaining the right inventory balance prevents overstocking or understocking, reducing carrying costs while ensuring a reliable supply, streamlining the supply chain, and enhancing overall efficiency.

Courier Partner Integration

Courier Partner Integration

Generative AI assists in selecting the most efficient and cost-effective courier partners for shipments based on real-time data and destination factors. By streamlining the logistics process, generative AI ensures timely and cost-efficient deliveries, enhancing customer satisfaction and supply chain performance.

Production Scheduling/Planning

Production Scheduling/Planning

Generative AI algorithms optimize production schedules by considering resource availability, production capacities, and order priorities. This optimization results in better resource utilization and shorter lead times, enhancing overall production efficiency and enabling quicker response to market demands.

Logistics Management

Logistics Management

Generative AI’s ability to recognize complex patterns enables it to optimize route planning, warehouse location selection, and transportation assignments. This streamlines the logistics process, leading to faster and more efficient movement of goods through the supply chain, reducing transportation costs, and improving delivery timelines.

Fleet & Vehicle Management

Fleet & Vehicle Management

By analyzing vehicle data and traffic patterns, generative AI optimizes fleet operations. This leads to reduced fuel consumption, lower maintenance costs, and improved delivery timelines, making the supply chain more sustainable and cost-effective.

How is Generative AI Different from Traditional AI for Supply Chain Use Cases

Traditional AI and generative AI both play significant roles in supply chain management, but they differ in their approaches and capabilities. While traditional AI relies on historical data and predefined rules to make predictions or decisions, generative AI takes a more creative and adaptive approach. Here’s how…

1. Creativity and Novelty

One of the key differentiators is generative AI’s ability to produce new and innovative solutions based on the patterns it has learned from the data. Unlike traditional AI, which operates within predefined parameters, generative AI can envision novel approaches to tackle unforeseen challenges in the supply chain. This creativity is especially valuable in dynamic and complex supply chain scenarios, where traditional AI models may struggle to adapt.

2. Complex Pattern Recognition

Generative AI excels at recognizing intricate patterns in data, making it well-suited for analyzing multifaceted supply chain information. While traditional AI models can handle relatively straightforward relationships, they may struggle with complex, non-linear, and interconnected patterns that are prevalent in supply chain processes. Generative AI’s advanced algorithms can uncover hidden insights and correlations, leading to more accurate predictions and better-informed decisions.

3. Adaptability to Changing Environments

Supply chains are subject to continuous changes, such as market fluctuations, consumer demands, and external disruptions. Traditional AI models rely heavily on historical data and may struggle to adapt quickly to these changes. In contrast, generative AI has a higher degree of adaptability. It can process real-time data and respond to unforeseen disruptions, enabling agile decision-making and quick adjustments to optimize supply chain operations.

4. Addressing Data Scarcity

Traditional AI models require large volumes of labeled data for training and may face challenges when data is scarce or difficult to obtain. Generative AI, on the other hand, can leverage unsupervised learning techniques to identify patterns and generate new data without the need for extensive labeling. This capability makes generative AI more suitable for scenarios where data availability is limited.

5. Complexity of Problem Solving

Supply chain management involves a myriad of interconnected processes and variables. Traditional AI may perform well in individual tasks, such as demand forecasting or inventory optimization, but could struggle to handle the complexity of solving multiple interrelated problems simultaneously. Generative AI’s ability to understand and optimize complex systems makes it well-suited for addressing the holistic challenges in supply chain management.

6. Exploration vs. Exploitation

Traditional AI is typically focused on exploitation, meaning it optimizes existing patterns and knowledge to achieve specific goals. On the other hand, generative AI has a higher emphasis on exploration, seeking new and innovative solutions by generating diverse possibilities. This exploration-driven approach can lead to breakthroughs and uncover novel opportunities for supply chain optimization.

According to an article by McKinsey & Company, successfully implementing AI-enabled supply-chain management has enabled early adopters to improve logistics costs by 15%, inventory levels by 35%, and service levels by 65%, compared with slower-moving competitors.

While traditional AI is valuable for well-defined and routine supply chain tasks, generative AI’s versatility, creativity, adaptability, and complex pattern recognition make it an indispensable tool for tackling the dynamic challenges and uncertainties present in modern supply chain management. As generative AI continues to evolve, its potential to revolutionize supply chain operations and drive efficiency and innovation is becoming increasingly evident to forward-thinking organizations.

Leena AI for Efficient Supply Chain Management

Leena AI‘s WorkLMTM-powered solution revolutionizes supply chain management by harnessing the potential of advanced AI capabilities. WorkLMTM stands for Work Language Model, which is a powerful language model that comprehends and generates human-like language, enabling Leena AI to understand complex supply chain data, processes, and interactions with ease.

With the WorkLMTM powered solution, Leena AI becomes a versatile and intelligent assistant, offering unparalleled support throughout the supply chain management process. Here’s how Leena AI helps make supply chain management more effortless and efficient:

Support at every stage of supply chain management

Leena AI provides support throughout the entire supply chain management process. It assists in streamlining and optimizing operations from procurement and inventory management to production, logistics, and distribution. By integrating AI algorithms and data-driven decision-making, Leena AI offers valuable insights and recommendations at each stage to enhance overall efficiency.

Predictive analytics

Through predictive analytics, Leena AI can analyze historical data, market trends, and other relevant factors to anticipate potential supply chain disruptions, demand fluctuations, and inventory requirements. This allows businesses to be better prepared for future challenges and make informed decisions to optimize their supply chain operations.

Real-time analysis and reporting

Leena AI facilitates real-time analysis and reporting by continuously monitoring data from various sources across the supply chain. This capability provides stakeholders with up-to-date information on inventory levels, production status, demand forecasts, and delivery schedules. With this real-time visibility, businesses can respond promptly to any issues and make agile adjustments to their operations.

Process automation

By employing process automation, Leena AI can automate repetitive and time-consuming tasks within the supply chain. This includes automating order processing, inventory tracking, invoicing, and more. Automation reduces the likelihood of human errors and increases the overall efficiency of the supply chain, leading to faster and more accurate operations.

Communication and collaboration

Leena AI facilitates effective communication and collaboration among supply chain stakeholders, both internal and external. It can integrate with various communication platforms and collaboration tools, enabling seamless information exchange and collaboration between different teams, suppliers, and partners. This enhances coordination, reduces communication delays, and improves overall supply chain responsiveness.

Continuous improvement

Leena AI is designed to continually learn and improve its performance over time. By analyzing historical data and feedback, it can identify areas where the supply chain can be optimized further. This iterative improvement process helps businesses achieve operational excellence and adapt to changing market conditions and customer demands effectively.

Results you can achieve by implementing Leena AI for Supply Chain Management

For the Leaders

Cost control through better forecasting and planning:

Leena AI’s predictive analytics aids in accurate demand forecasting and inventory planning, reducing excess inventory and minimizing carrying costs.

Increased visibility across the supply chain:

Real-time analysis and reporting offer leaders better insights into the entire supply chain, enabling them to make data-driven decisions and proactively address potential bottlenecks.

Identifying areas of improvement through AI:

Leena AI’s continuous improvement approach helps identify inefficiencies and suggests areas where optimization can lead to cost savings and enhanced performance.

Staying ahead of competitors in terms of technological advancements:

Leveraging AI-driven supply chain management gives businesses a competitive edge by adopting cutting-edge technology and staying ahead in the market.

For the Supply Chain Team

Ability to take proactive actions:

With real-time data and predictive insights, the supply chain team can anticipate and address potential disruptions before they escalate, enabling them to take proactive measures.

Data and insights to improve processes:

Leena AI provides data-driven insights that help the supply chain team make informed decisions, optimize processes, and improve overall efficiency.

Track performance metrics in real-time:

Real-time analysis and reporting enable the supply chain team to monitor key performance indicators (KPIs) and track their performance at various stages of the supply chain promptly.

Access to information for better efficiency and performance:

By facilitating communication and collaboration, Leena AI ensures that the supply chain team has access to the right information at the right time, promoting efficient decision-making and streamlined operations.

Advancements in artificial intelligence (AI) have revolutionized various industries, and supply chain management is no exception. By integrating AI-powered solutions like Leena AI, businesses can unlock unprecedented levels of efficiency and optimization within their supply chain operations. Leena AI’s sophisticated WorkLMTM-powered capabilities enable real-time data analysis, predictive analytics, and process automation, facilitating faster decision-making, seamless collaboration, and improved communication among stakeholders. With the ability to continuously learn and adapt, Leena AI empowers businesses to stay agile in the face of dynamic market conditions, proactively address disruptions, and capitalize on emerging opportunities. By implementing Leena AI for supply chain management, businesses can achieve cost savings, enhance customer satisfaction, and gain a competitive advantage, ultimately paving the way for long-term success and growth in an increasingly competitive business landscape.

Frequently Asked Questions

How is generative AI used in logistics?

Generative AI plays a crucial role in logistics, revolutionizing route planning, warehouse location selection, and transportation assignments. Its implementation results in remarkable advancements in the movement of goods through the supply chain. By optimizing routes and warehouse placements, businesses achieve higher levels of efficiency and cost-effectiveness. Transportation assignments are streamlined, reducing delivery times and ensuring timely customer satisfaction. The AI-driven logistics approach empowers companies to respond swiftly to dynamic market demands and unforeseen challenges. With faster and more efficient goods flow, businesses can enhance their competitive edge and achieve greater success in the ever-evolving world of logistics.

What are the applications of generative AI in the supply chain?

Generative AI is widely applied in supply chain management. It optimizes demand forecasting, predictive maintenance, inventory management, courier partner integration, production scheduling, logistics management, and fleet & vehicle management. By leveraging data and advanced algorithms, generative AI enhances decision-making and efficiency throughout the supply chain. These applications enable businesses to anticipate demand, minimize downtime, optimize inventory levels, streamline logistics processes, and improve overall supply chain performance, leading to increased customer satisfaction and cost savings.

Where is AI used in logistics?

AI is utilized in logistics for various applications, including route optimization, vehicle routing, demand forecasting, real-time tracking, and automated warehouse management. These applications encompass route optimization, where AI algorithms analyze vast datasets to determine the most efficient routes for transportation. Additionally, vehicle routing is optimized by AI to allocate resources effectively, while demand forecasting helps businesses anticipate customer needs accurately. Real-time tracking enables precise monitoring of shipments, and automated warehouse management ensures seamless inventory handling. The integration of AI in logistics transforms supply chain processes, driving productivity and customer satisfaction.

What are the areas where AI and machine learning are being used in supply chain and operations?

AI and machine learning technologies play crucial roles in supply chain and operations, offering a diverse array of applications that revolutionize industry practices. These include demand forecasting, predicting customer needs with data-driven accuracy, optimizing inventory management to ensure optimal stock levels, and efficiently handling logistics to streamline the movement of goods. Additionally, AI-driven predictive maintenance enhances equipment reliability, reducing downtime and maintenance costs. Quality control processes benefit from AI-powered inspections, ensuring products meet high standards. With their multifaceted applications, AI and machine learning continue to drive innovation and efficiency across supply chain and operational domains.

What is supply chain optimization?

Supply chain optimization is a comprehensive process that harnesses the power of advanced techniques and technologies, such as AI and machine learning. By incorporating these cutting-edge tools, supply chains can streamline and enhance various critical aspects, including inventory management, transportation, and production planning. The ultimate goal is to achieve higher levels of efficiency, reduce operational costs, and deliver improved customer satisfaction, all of which are vital for sustained success in today’s competitive business landscape.